Investment Projects

1. Project Selection

Our project selection process includes identifying, developing, financing and operating capital-intensive projects with long-term cash flow characteristics in the natural resources and infrastructure sectors.

Our projects should have strong local and government support and should help solve challenges or achieve community objectives.

We will combine experienced local operational know-how and resources with the latest technologies from the around the world and then apply a high degree of financial sophistication and planning to achieve a successful outcome with high internal rates of cash flow-based return.

2. Operational Units

- Renewable Energy

- Property Development

- Medical and Food

- Mining

- Oil and Gas

- Marine Services

Investment Themes

- Food Security (Sashi Inchi) & Health

- Affordable Housing

- Green Energy and Technology

- Asset-based investments

3. Highest Corporate Standards

Our ambitions are on a global scale as we embark on our mission to make a positive difference in the world.

We hold ourselves to the highest corporate standards of reporting, transparency, operations, stewardship and corporate citizenship.

Company Structure and Financial Backing

Our ambitions are on a global scale as we embark on our mission to make a positive difference in the world. We hold ourselves to the highest corporate standards of reporting, transparency, operations, stewardship and corporate citizenship.

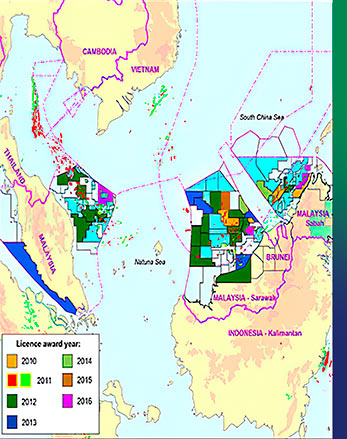

1. Sarawak Oil & Gas Scenario

Oil exploration in Malaysia started at the turn of the century and the first commercial discovery was made by the Royal Dutch/Shell group in 1910, onshore at Miri in the state of Sarawak. Sarawak has 60 oil & gas producing fields, 26 oil and 34 gas which produce an average of 850,000 boepd yet another 206 discovered fields which are yet to be monetized. Petronas had spent around USD70 billion into Sarawak prolific basins of gas-prone carbonate SW & Central Luconia & sandstone Baram Delta.

Sarawak’s Real GDP in 2014 is about RM78.6 billion and 44% came from the Oil & Gas sector. In terms of export receipts, 76% was contributed by the Oil & Gas sector of which 55% was contributed by the Liquefied Natural Gas and 21% from crude petroleum and petroleum products.

Sarawak Current 2017 Bidding Round

Blocks offered are oil-prone around recent discovery: WB5-01, BL7-00 and BL9-00 are all offshore and SK2-00 is onshore.

Sarawak Onshore – Fields for Acquisition

Propose to Acquire Adong Kecil West 1 in Block SK-333 with recoverable of 10 MMBO

Sarawak Onshore – R/C PSC terms

2. In-housed EOR Technology

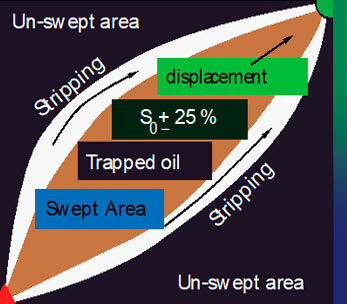

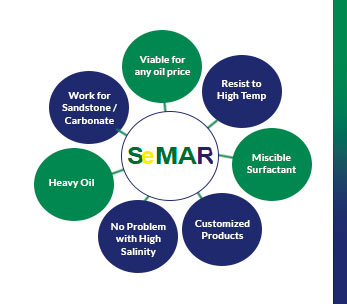

SeMAR (Solution by Chemical Modifier to Enhance Recovery) is a special bio-degradable chemical modified to accelerate recovery of oil fields developed in-housed by Indo-Pacific Resources Inc. R&D & Instituit Teknologi Bandung. On a low concentration in a solution of system, SeMAR has the ability to imbibe and alter the amount of energy on the surface or interfacial layers of the system.

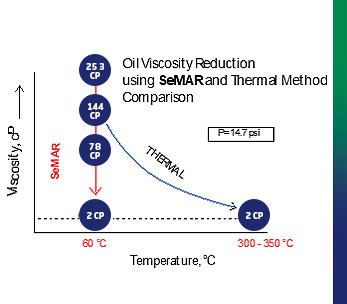

SeMAR injection is an EOR method that uses a chemical to mobilize the residual oil saturation. SeMAR is also known as a wetting agent that takes part on lowering the interfacial tension of a fluid and helps distribute the fluid on the surfaces of the rock. This chemical could also reduce fluid formation viscosity significantly (suitable for heavy oil reservoirs).

* Three (3) published papers has been appeared in SPE Journals and Proceedings. 22 Oil fields in Indonesia, Oman, and Sudan have been tested encouragingly with average 250 to 350 bopd increased after injections.

Workflow of SeMAR Implementation to Improve Oil Production and Recovery

- Field sample preparation (oil, water & core).

- Laboratory Test, Assessment, Optimization & Method Selection.

- Well candidate selection.

- Implementing of Reservoir Modification by Stimulation (Huff & Puff) Injection.

- Monitoring to measure production from injected well and connectivity respond at adjacent wells.

- Extended Stimulation base on the best respond from injected well.

- Pilot Continues Injection at Limited Pattern.

- Full Scale continues injection.

3. PALM OIL (BIODIESEL) - HiFFA GWR Biodiesel

10 year supply agreement with Sumatra-based Indonesia plantation.

Long-term lease for Perak.

based Indonesia plantation.

Collection point in Perak.

Membership in RISDA for the acquisition of palm oil.

Kuala Lumpur processing, warehouse and shipping facility

Milling facility in Sumatra (land available for expansion)

Butanyl plant planned for Perak

- Feedstock for Biodiesel

- Production of biodegradable grease

- Marine Services

- Palm Oil

- Butanyl planned

Import Export license from Palm Oil board in Malaysia

Certification for export to EU

Biodiesel feedstock pre-treatment process

Butanyl production plant Grant

Ministry of Science, Technology and Innovation

Application pending